We retrofit analog testing machines into reliable, accurate, and connected digital systems—without replacing your entire setup.

Benefits

- Higher accuracy & repeatability

- Fewer breakdowns and lower maintenance

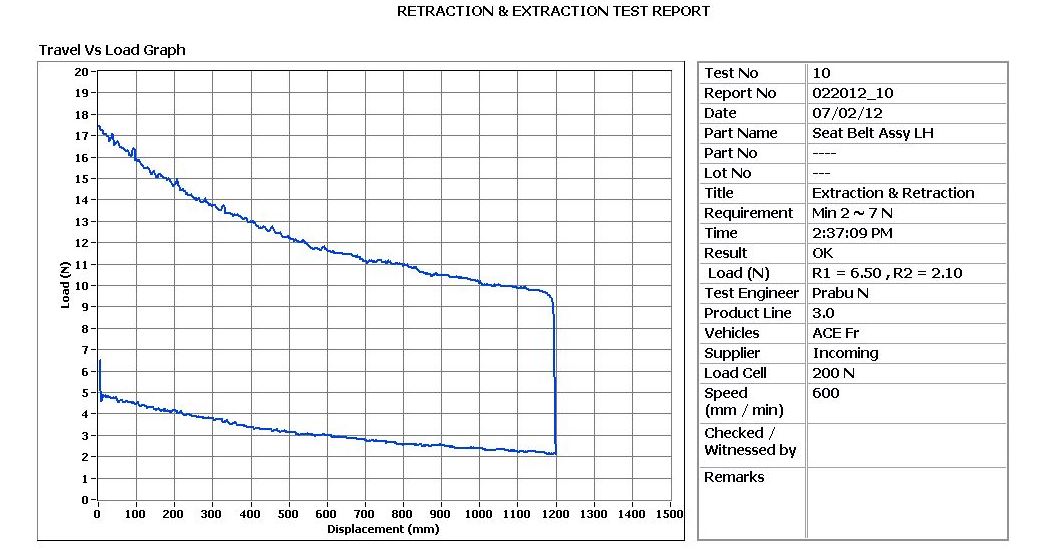

- Digital records for audits and analytics

- Extend machine life at a fraction of replacement cost

What we upgrade

- Universal testing machines, hardness/impact testers, torsion/pressure rigs, custom benches

- Extruders, motor test dyno, engine test dyno

- Analog gauges and chart recorders → high‑resolution ADCs with digital readouts

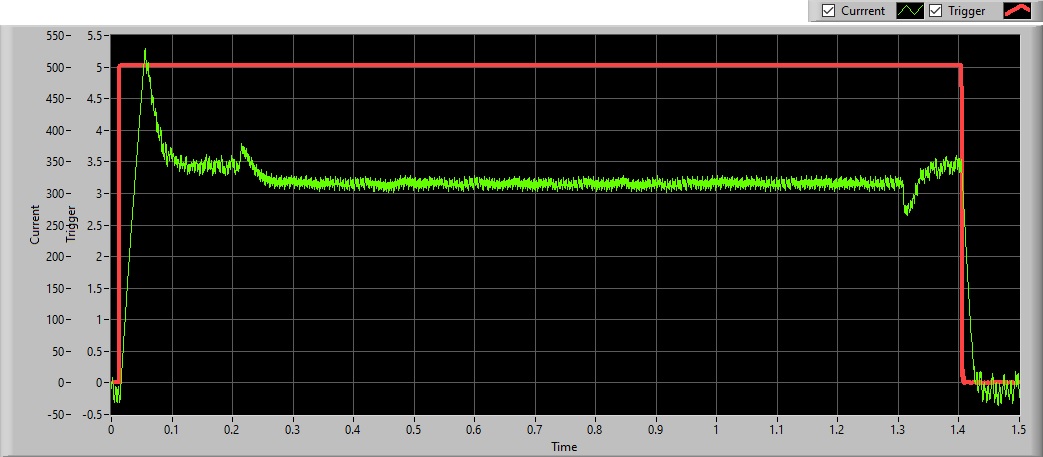

- Manual controls → closed‑loop automation (servo/stepper/hydraulic/pneumatic)

- Paper logs → on‑screen visualization, USB/network data logging, optional cloud sync

Typical scope

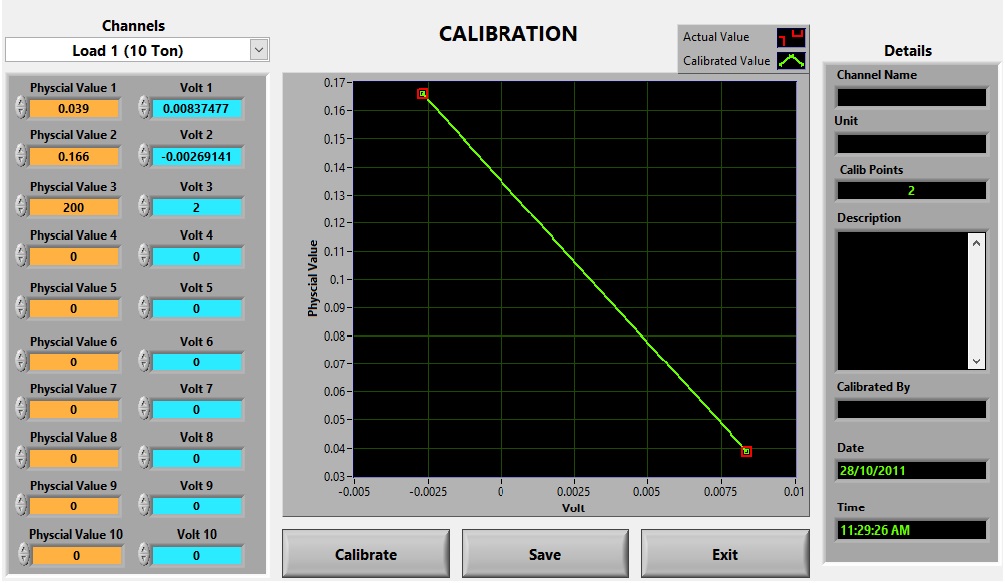

- New sensors or re‑calibration of existing sensors (load/strain/pressure/temperature)

- Industrial‑grade signal conditioning and noise‑immune cabling

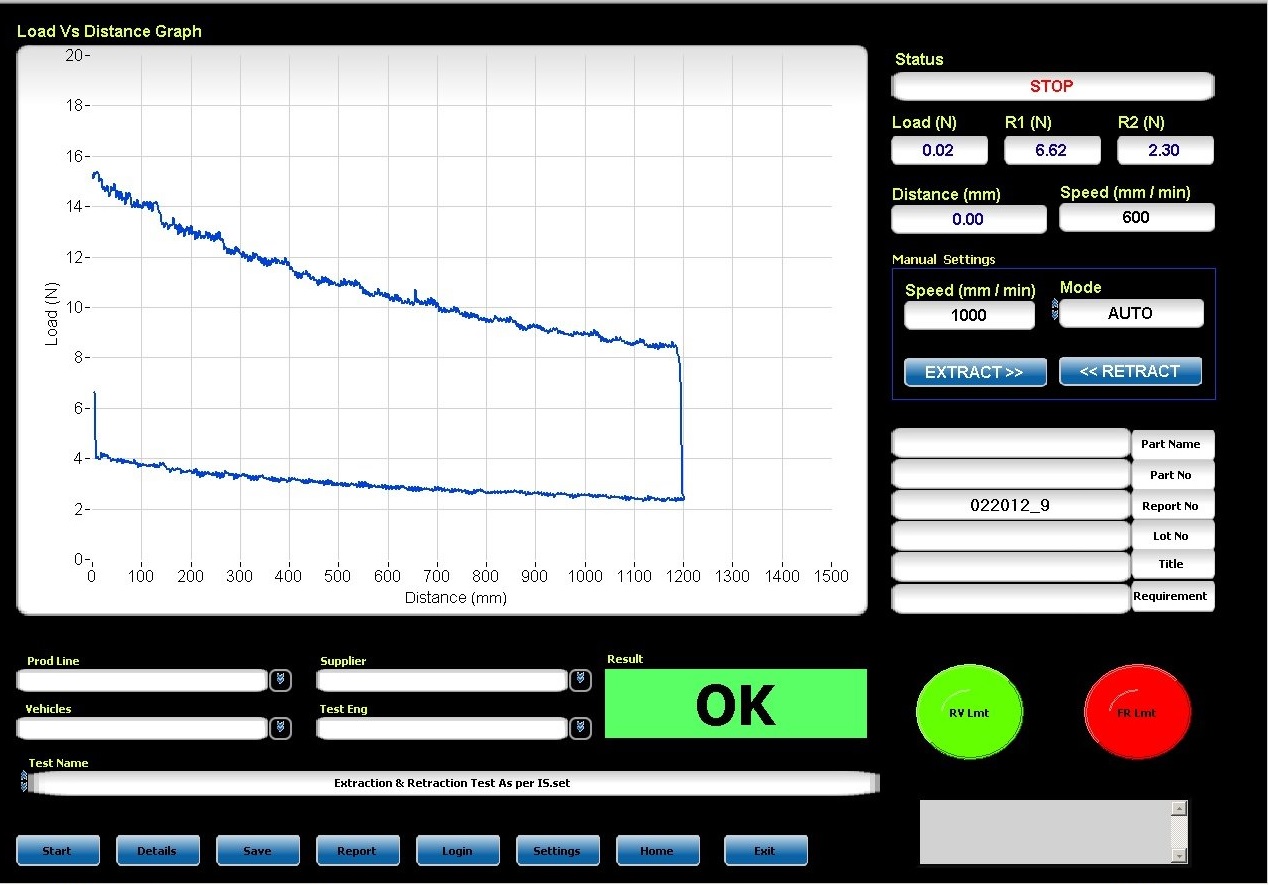

- Touchscreen HMI (PC or embedded), alarm & safety interlocks

- Protocols: Modbus TCP/IP, CAN, Ethernet, RS‑485/RS‑232; database and report generation

- Compliance‑friendly calibration workflows and traceable reports

Screens & Reports

Sample software UI pages and report outputs from recent upgrades.